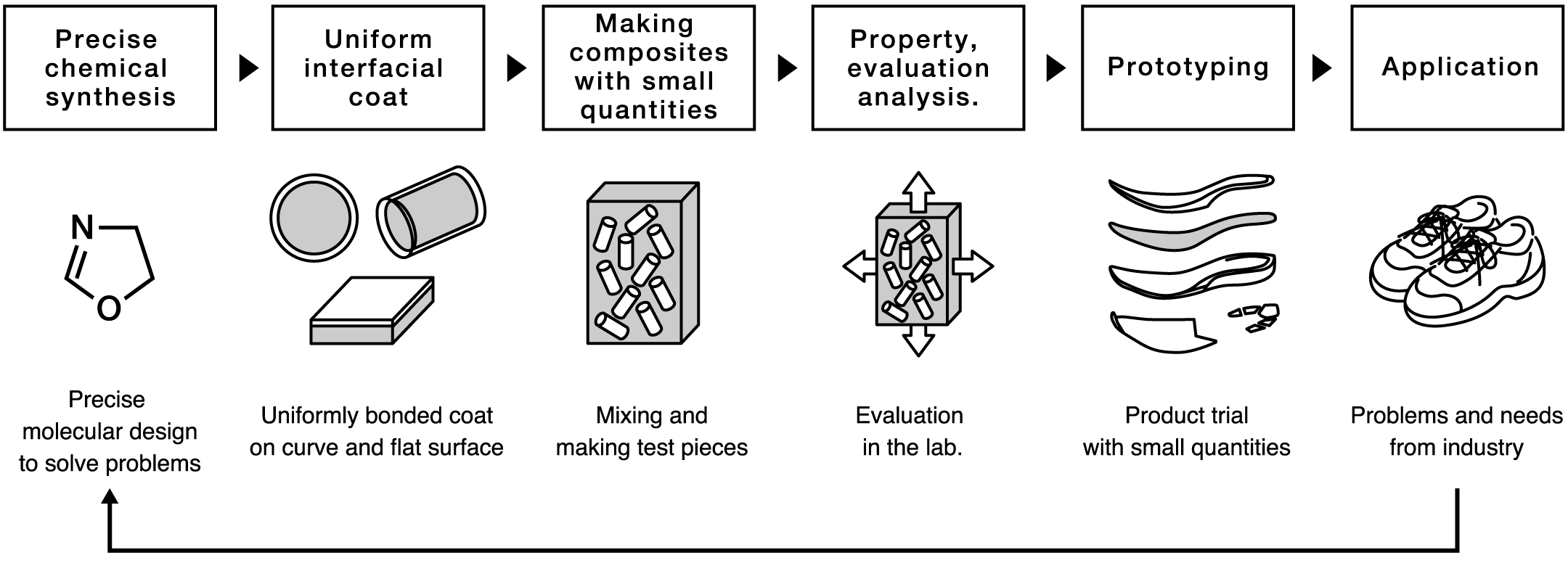

Based on needs and unsolved problems, we induce the innovation by composites from “Interface” and “Original Molecular Design”

“Without the precise interfacial design from molecular levels, impossible to reach commercialization !” By performing such unique and innovative development, we contribute the industrialization.

From the collaboration and the serendipity, triggered by international and domestic encountering, we conduct the innovative challenges with passion.

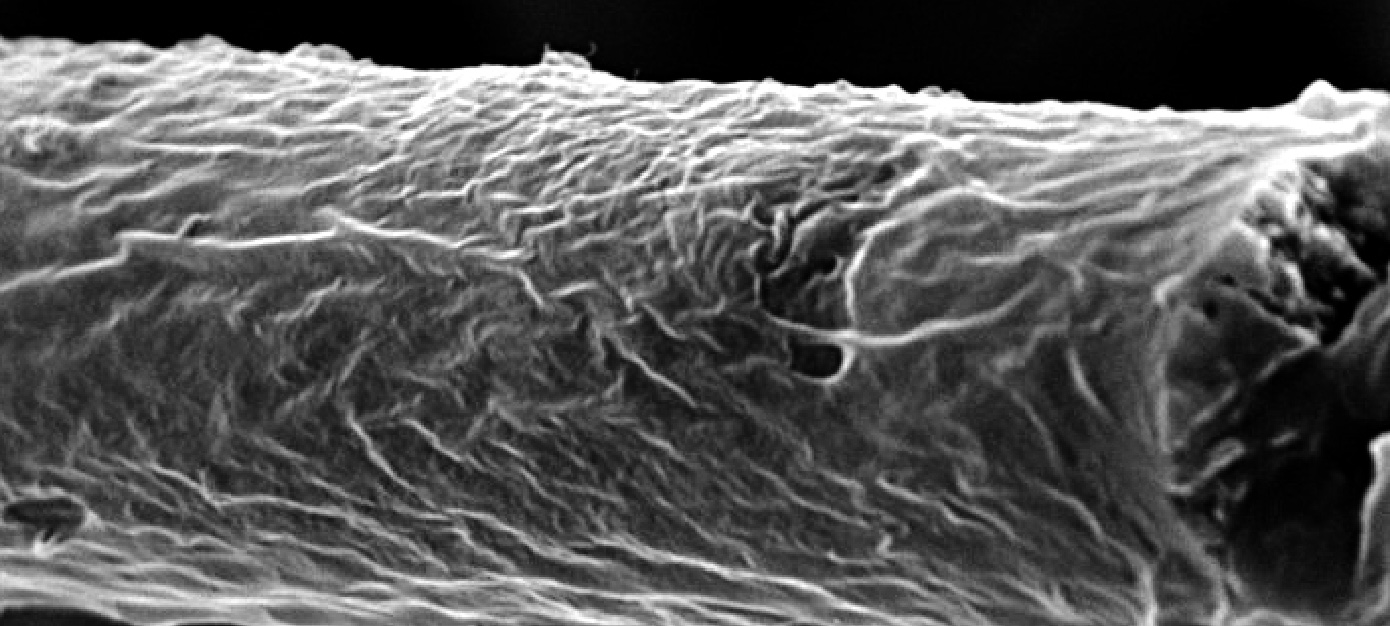

We focus on the interface, mainly, between

carbon materials, such as carbon fiber, diamond, carbon nanotube, nano carbons etc and resins. We perform the quantitative analysis of acid groups on carbon fiber and make the precise interfacial design.

We can make the reactive polymer design, mainly focusing on highly reactive oxazoline, to solve problems in the end-use products. Based on the molecular design, we perform chemical synthesis.

We can utilize a series of equipment from synthesis, interfacial coat, melt mixing with thermoplastic polymers, compression molding to make test pieces of composites, up to evaluation, such as strength, with gram quantities. We can test inspired ideas immediately.

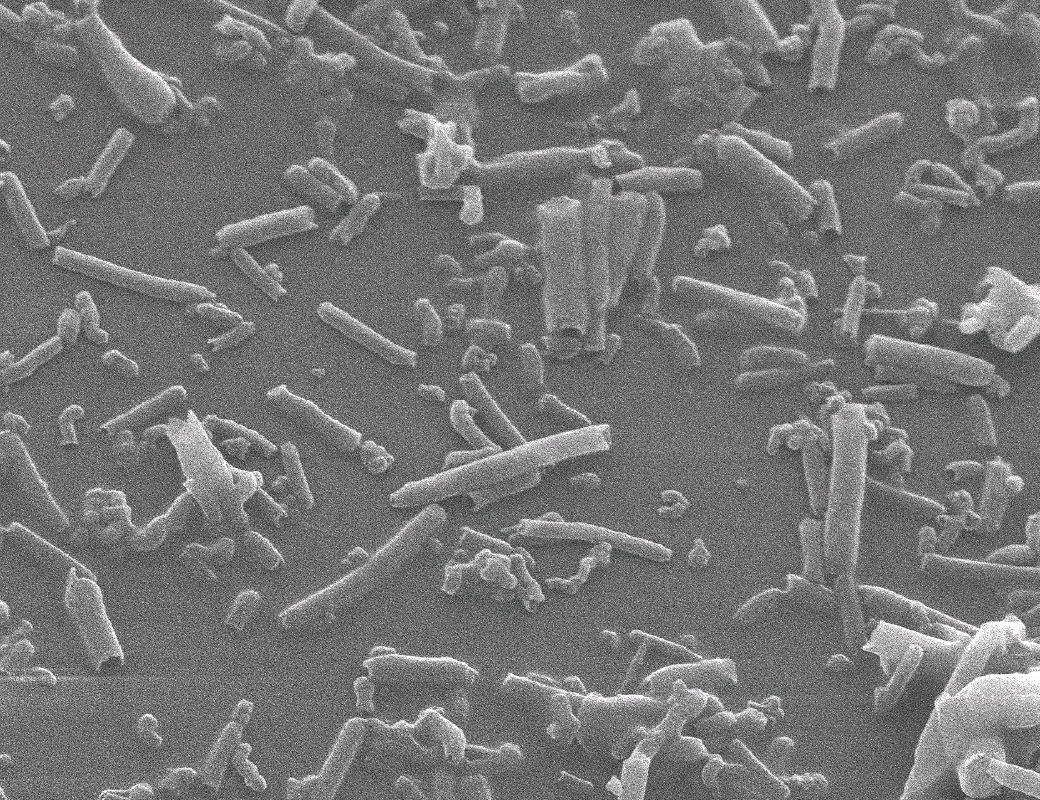

First in the world, we have successfully synthesized the original reactive polymers using oxazoline. By utilizing the reactive polymers, we conduct the interfacial research on carbon materials, such as carbon fiber and diamond, which are uniformly coated by carbon nanotube with chemical bonding.

This interface, which is precisely designed, has

1. Chemical reactive effect

2. Physical anchoring effect

With the synergy of the two effects, we have demonstrated the dramatic enhancement in the mechanical strength of carbon fiber polymer composites and in the holding strength of diamond particles.

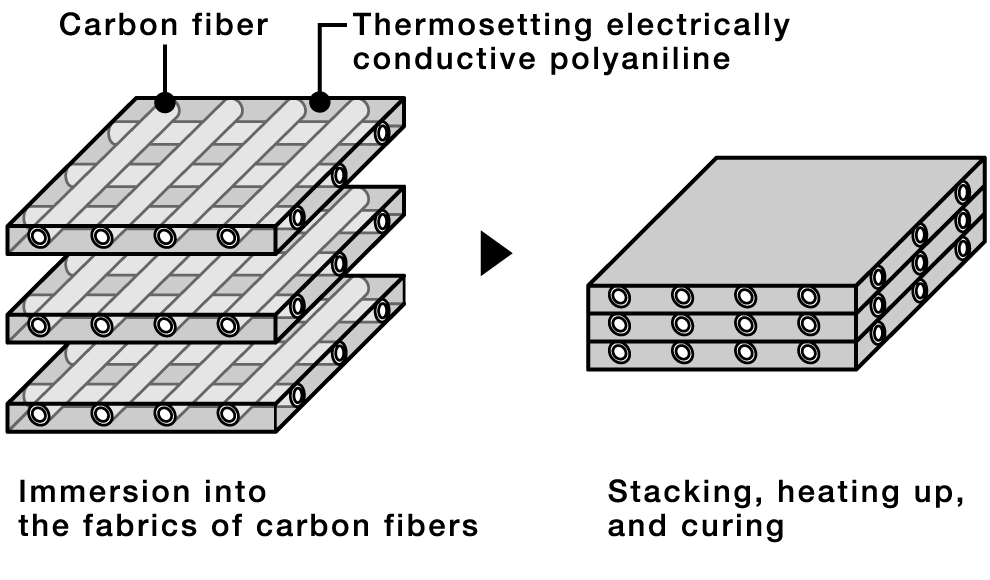

First in the world, delivering these three characteristics into the original thermosetting electrically conductive polyaniline, we carry out research and development. By utilizing this as the matrix of carbon fiber reinforced plastics (CFRP) (see illustration), we have conducted research collaboration with Japan Aerospace Exploration Agency (JAXA) and the University of Tokyo, resulting in the world first successful demonstration about no damages of our developed CFRP by the artificial lighting test (Not burned : our developed CFRP, Burned : conventional CFRP). We continue the further development for the practical uses.

Research and development of colorless and transparent X-ray shielding composites has been carried out with Hirosaki University, Institute of radiation emergency medicine and Graduate school of health science, resulting in the success of the world's first. Currently, the further improvement of X-ray shielding property having colorless and transparency, together with the research and development toward practical applications.

We carry out the following new developments through new research collaboration.

From the collaboration and the serendipity, triggered by international and domestic encountering, we carry out the innovative challenges with passion.

Please contact us from the requests.

Yamagata University, Center of Excellence (YU-COE)

Leader : Tatsuhiro Takahashi

| Jun Matsui | Faculty of Science, Material and Life Chemistry, Professor | Nano thin layer |

|---|---|---|

| Kazuo Hara | Faculty of Science, Mathematical Science, Asso. Professor | Artificial Intelligence |

| Yuji Kume | Faculty of Engineering, Mechanical System, Asso. Professor | Metal |

| Toshiyuki Sugimoto | Faculty of Engineering, Information and electronics, Asso. Professor | Electrical and Electronic |

| Hiroki Tomori | Faculty of Engineering, Mechanical System, Assist. Professor | Mechanical System |

| Teruya Goto | Faculty of Engineering, Project Researcher (Assist. Professor) | Polymer |

| Giuseppe Milano | University of Naples Federico II Industrial Chemistry Professor |

Simulation |

|---|---|---|

| Tomohiro Yokozeki | The University of Tokyo, Aerospace, Asso. Professor | Aerospace composites |

| Toshio Ogasawara | Tokyo University of Agricultural and Technology, Mechanical System, Professor | Aerospace composites |

| Takao Okada | Japan Aerospace Exploration Agency (JAXA), Senior Researcher | Aerospace technology |

| Tsunehisa Suzuki | Akita Prefectural University, Advanced machining, Professor | Grinding |